Looking for replacement parts? Click Here to visit our Web Store!

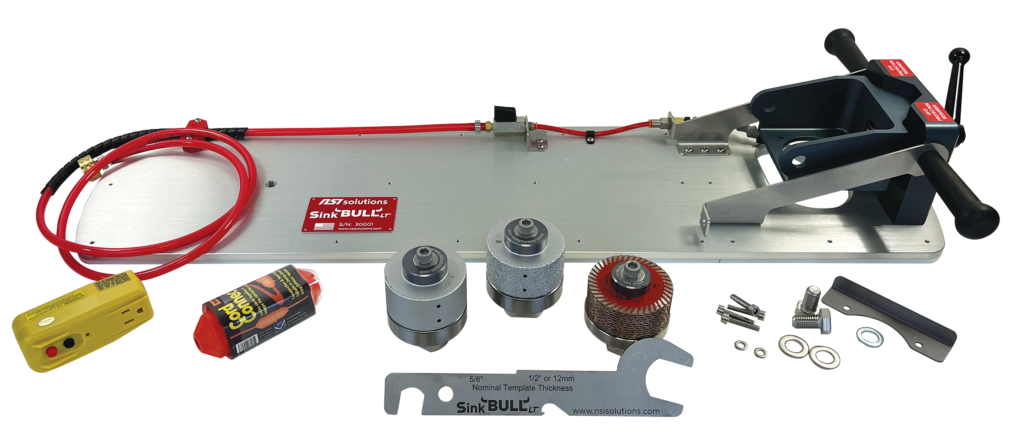

Sink BULL™LT

The Sink BULL™LT is the newest version of our heavy-duty, manual, sink milling machine specifically designed for grinding under-mount sink cutouts. The Sink BULL™LT utilizes a simple, rigid, powerful design and your own inexpensive, shop-made, templates to make sink grinding easy and fast. The Sink BULL™LT makes CNC quality sink cutouts a simple task for every fabricator.

Sink BULL™LT - making perfect sink cutouts the simplest job in your shop

CHECK OUT THE NEW UNBOXING & ASSEMBLY VIDEO HERE

The Detailed Sink BULL™ Process

-

Use the template to trace the sink profile onto the stone.

-

Rough out the center of the sink with an appropriate saw/grinder and blade.

-

Clamp the template in place - two clamps are usually sufficient.

-

Attach the Rapid ZTM-CUT grinding wheel onto the Sink BULLTM

-

Using the include custom wrench as a height gauge, adjust the height so the bearing rides against the template.

-

Rough grind the cutout to shape by running the Rapid ZTM-CUT around the inside of the template, grinding away stone, until the bearing is riding against the template all the way around.

-

Replace the Rapid ZTM-CUT with the Rapid ZTM-DRUM - Coarse and continue around the template a second time.

-

Finish the cutout by switching to the Rapid ZTM-DRUM - Fine and grinding around the whole template for the third and final time, or until the cutout is smooth.

-

The cutout is complete and ready to polish.

Less Skill Needed

Less Work Required

-

Any Fabricator can achieve CNC quality cutouts with minimal time and effort

-

Less skill and effort required then traditional hand fabrication

-

Less hand, wrist, and arm fatigue compared to hand shaping

-

Superior results can be achieved quickly

-

Less potential for mistakes

-

Smooth, consistent, perpendicular edges are achieved automatically

Quality Construction

-

Durable construction of anodized aluminum, stainless steel and corrosion resistant hardware

-

Powered by a heavy duty, 15 amp, Makita Grinder model GA7021 or GA7020 (USA), GA7031 (Canada), GA7040S01 (Australia) - sold separately

-

Long base spans the template and makes it extremely stable in use, which means no "tipping" and smaller template margins.

-

Portable - can be used on the job site

-

Strong, single lever height adjustment

-

Simple external water feed

-

Made in the U.S.A

Creative Uses for the

Sink BULL™

This video demonstrates another use for the NSI Solutions Sink BULLTM - using

simple templates to grind a complicated island profile to shape.

We met Bill Arcieri, owner of The Kitchen Center at TISE 2018. He made the following comment about the Sink BULL:

"The sink BULLTM has been a time-saver for our shop. The ease of adjustments and inexpensive tooling is a huge plus for a small shop like ours. Not only do we use it for sinks but we use it to clean up radius ends on islands and we can put our newest guy on it and in a few minutes he is cutting like a pro. NSI has done a great job with this and it is a must have!"

Bill Arcieri

The Kitchen Center

Grand Junction, Colorado